![]()

Collaborative Research Center/Transregio 63

"Integrated Chemical Processes in Liquid Multiphase Systems"

"Integrated Chemical Processes in Liquid Multiphase Systems"

![]()

Collaborative Research Center/Transregio 63

"Integrated Chemical Processes in Liquid Multiphase Systems"

Sub-Coordinators: Prof. Dr. Reinhard Schomäcker Dr. Matthias Stein

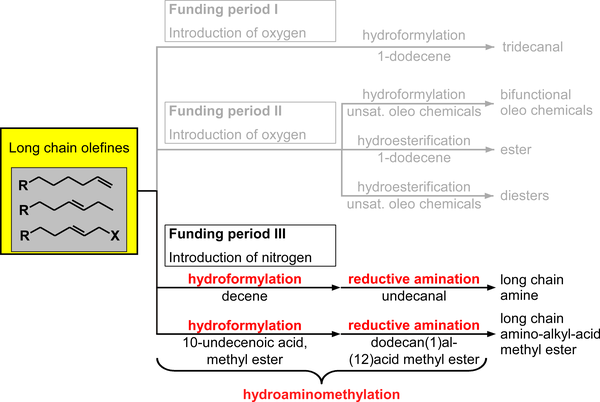

The development and design of novel processes for the fine chemical production from sustainable feedstock requires a careful and thorough investigation and characterization of the new and more complicated systems.

Upon introduction of novel substrates, the chemical and physical-chemical properties of the different reactive systems may change and need to be characterized.

In project area A, the thermodynamic properties and reaction kinetics of complex solvent mixtures in different solvent systems (thermomorphic and micellar solvent systems and pickering emulsions) are being investigated. The results from project area A provide the physical and chemical foundations for further process design and optimization.

Systems of interest are the hydroformylation reaction of long-chain olefins and the reductive amination of the generated aldehyde to a tertiary long-chain amine.

A2 (Schomäcker): Investigation of homogeneously catalyzed reactions in micellar systems

A3 (Hamel, Seidel-Morgenstern): Kinetics of reductive amination and hydroamination in reactive multiphase fluid systems

A4 (Stein, Sadowski): Choice of solvent for selective control of kinetics and thermodynamics of chemical reactions

A9 (Sadowski, Enders): Solubilization of weakly polar compounds in micellar systems

A10 (Böhm, Hecht, Kraume): Gas/liquid mass transfer in reactive multiphase systems

A11 (Seidensticker, Vogt): Homogeneously catalyzed reductive amination of long-chain aldehydes and hydroaminomethylation of long-chain alkenes with integrated separation in thermo-regulated solvent systems

The tools and methods applied in this project area range from macroscopic descriptions of the gas-liquid transport to the characterization of the thermodynamics of mixed-solvent systems under process conditions and the development of reaction kinetic network models. By design and control of the process, the chemical reactions are controlled to produce the desired product in high yield and purity.